Double beam engine

In 2021 it will 50 years since Blists Hill Victorian Town Museum opened to the public. In keeping with the areas innovative past, the Blists Hill museum was a first for a new type of open air museum. We were thrilled to be invited by The Ironbridge Gorge Museum to undertake an inspection of the double beam engine and structure at the Blist’s Hill Victorian Museum to determine if the exhibit could be reopened for close viewing by the public or brought back into use as a part of the 50 year celebrations.

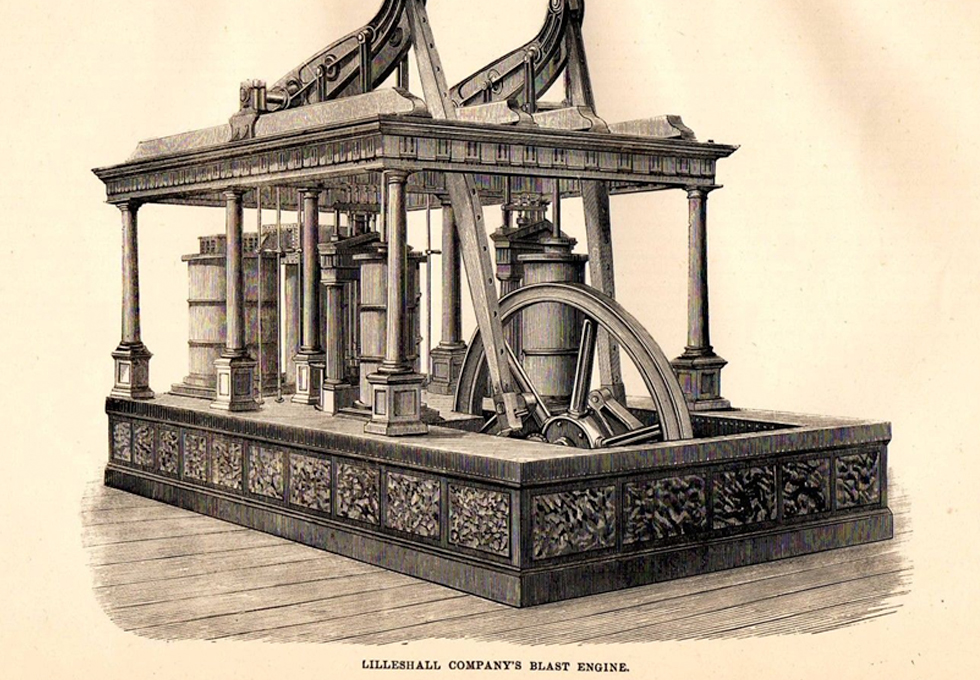

The double beam engine was built by Murdock Aitken and Company of Glasgow in 1851 for use by the Lilleshall Company to increase production at it’s Priorslee works. The works were situated in what is now the Hollinswood Road area of Telford. The beam engine was so successful that the Lilleshall Company also started fabricating the engine.

As is typical with Victorian design and fabrication intricate details are added to the support structure such as doric columns and ornate detailing on the beams, even though this was to be in a steel works. This sort of detailing is no longer common-place in today’s engineering, with functionality and cost efficiency taking precedence over the Victorian values.

The design of the double beam engine was innovative as it used a single flywheel to power two parallel beams that provided the compressed air to the furnace. In case you haven’t been fortunate enough to see a fly wheel and beam engine in motion, a simplified example is above.

The double beam engine was in full time use until the early 1900’s and was then used as a standby engine until the works were closed in 1951.

Following the closure of the Priorslee steel works and during the development of the Blists Hill Museum the double beam engine was to be moved to be an exhibit at the new innovative open air museum.

In 1971, the antecedent of Thomas Consulting, the Telford Development Corporation were tasked with designing the new support structure for the double beam engine. Reinforced concrete pits were designed to support the flywheel and a steel structure to support the double beams where these used to bear onto masonry walls in the original location.

The scope of our inspection was to determine the works required to allow the exhibit to reopen as a static exhibit and additional works to allow the double beam engine to be put back into use thereafter.

Unfortunately, the inspection found that the base slab to the blow cylinders did not extend far enough to support the base of the blow cylinders and that supports for the flywheel were not accurately positioned to support the base plates. No moving part was installed accurately to line and level, which is paramount in this installation of this kind.

The lack of accurate positioning created eccentricities into the system that meant other areas were not correctly aligned. To enable the double beam engine to be brought into use during the 1980’s areas of steel were cut from the supporting columns and cylinders due to clashes with moving parts.

It is disheartening that a valuable piece of engineering history, that worked for almost a century in its original position, should not have been brought back into use 40 years ago due to a lack of accuracy in its installation 50 years ago. Due to these defects, damage has been sustained to the structural frame supporting the beams due to out of plane forces. To enable the double beam engine to be brought back into use significant works are required to allow the mechanical items to be installed accurately to line and level. If only as much care and pride was taken in these works 50 years ago the double beam engine could still be in use today.